Organizations with a passion for quality, reliability, efficiency and safety are using real-time insights generated from AI-powered predictive maintenance programs to anticipate and avoid potential issues while mitigating negative impact.

A shift from reactive maintenance, or handling issues in real-time, is not just a technological evolution; it's a strategic decision. With predictive maintenance, organizations are more efficient, save money and increase overall reliability.

The power of data and analytics for predictive insights

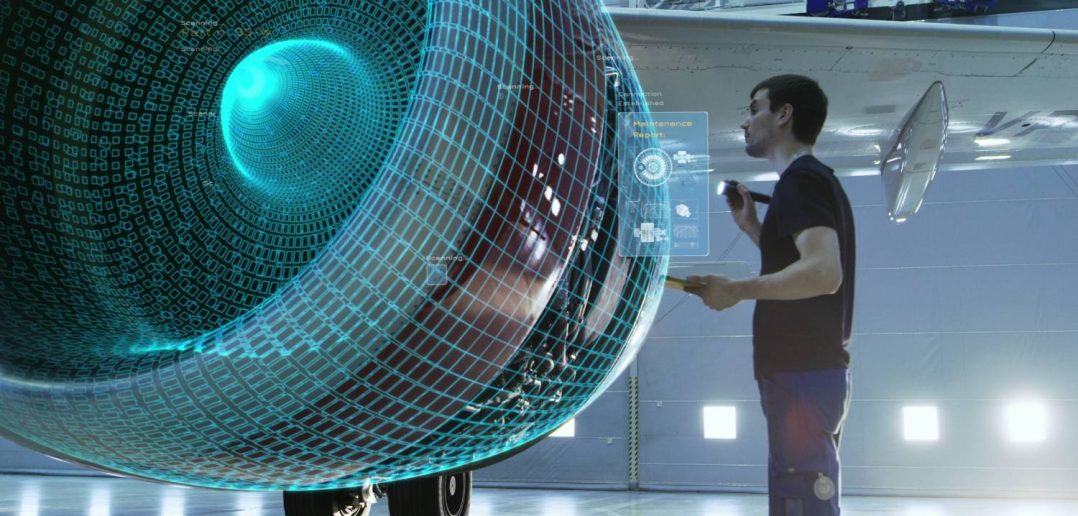

For predictive maintenance, data-driven insights are important. With AI and advanced analytics, organizations can collect and quickly analyze vast amounts of data generated by sensors embedded in equipment. These sensors continuously monitor parameters, providing real-time snapshots of the machinery's overall condition and health.

These insights help decision-makers predict potential failures and schedule required maintenance to reduce downtime and improve operational and cost efficiency, reliability and safety. This process of improvement ensures that predictive maintenance evolves with the changing dynamics of equipment performance, organizational objectives and industry standards.

Predictive analytics: What it is and why it matters

Predictive maintenance in the real world

Let’s talk about a few examples of the impact of predictive maintenance in the real world.

Georgia-Pacific tackled COVID-19 challenges with predictive maintenance, boosting equipment efficiency by 10% and slashing downtime by 30%. Georgia-Pacific's secret? Using advanced analytics to combat the challenges of surging demand and supply chain disruptions.

Volvo Trucks and Mack Trucks cut unplanned vehicle downtime using sensor data and AI solutions, reducing diagnostic time by 75% and overall repair time by 25%. This streamlined approach maximizes vehicles' on-road time, minimizing service disruption costs through efficient, accurate and proactive repair operations.

And Lockheed Martin is transforming aircraft maintenance and fleet management with data-driven insights. Reducing downtime by 2,000 hours in six months helped one of Lockheed Martin's largest C-130J operators to achieve a 2.6% increase in mission-capability rate—ensuring consistent aircraft readiness for critical military and humanitarian missions.

These examples underscore the versatility and impact of predictive maintenance in enhancing operational efficiency, minimizing costs, and ensuring reliability across different industries. Predictive maintenance adoption delivers these tangible benefits and more across industries, spanning diverse market sectors.

Understanding the financial impact of predictive maintenance

Predictive maintenance redefines cost efficiency by moving away from fixed schedules to dynamic, need-driven models, yielding substantial savings. This approach minimizes unnecessary maintenance activities, reduces labor costs, and optimizes the use of resources. Beyond preventing breakdowns, predictive maintenance enhances overall equipment performance, reliability, and safety. By incorporating these broader opportunities, a more cost-effective maintenance strategy can be adopted that delivers a significant return on investment.

It's about more than just technology

Shifting to predictive maintenance isn’t just about technology—it demands a cultural change. Organizations need a workforce that is comfortable with new technologies and embraces a mindset of continuous improvement. Recognizing predictive maintenance as an organizational journey, no two paths are the same and are based on goals and maturity.

Success requires a continuum of analytic approaches (business rules to anomaly detection to AI/ML models), operational paradigms (edge-to-cloud analytics to automated decision workflows), and diverse organizational roles (equipment operators to subject matter experts to data scientists). Acknowledging this continuum means success, with each organization forging its own path guided by a commitment to innovation.

Predictive maintenance is not just a buzzword; it's a strategic investment with real benefits. By tapping into data insights, organizations boost operational efficiency, cut costs, enhance reliability and safety, and foster a culture of continuous improvement. It’s not just about today; it's about a pathway to more sustainable and competitive industries.

Get more tips on how to accelerate and scale your PdM initiatives with AI and real-time analytics