As the holiday season approaches, businesses may be bracing for what’s been all too common in recent years – supply chain disruption.

Retail and consumer goods industries have been hit with disruptions from every direction: profound shifts in consumer preferences, materials shortages, weather events, and geopolitical activities, to name just a few.

A single retailer with an aggressive marketing plan, like Temu, or a severe drought causing restricted access to the Panama Canal can trigger supply chain issues almost overnight. Some experts believe that the level of disruption in the last few years marks a fundamentally new era – and while the types may fluctuate in the coming years, the volume will likely remain high.

Happily, we’re not helpless – far from it. Thriving in today’s global economy is possible with a high-velocity supply chain. One with complete visibility from source to customer doorstep, advanced and streamlined facility automation, and timely collaboration with carriers, customers, suppliers, and partners. This kind of supply chain not only minimizes risks but also empowers businesses to reduce costs, retain and expand their customer base, and optimize operations. It turns the supply chain from being a potential business risk to a critical differentiator.

Increasingly powerful technologies can help you and your organization observe what’s happening in real time and even predict previously unpredictable events, like fast-shifting consumer trends, sudden market disruptions, and bourgeoning shortages.

Being able to “see into the future” in this way creates a transparent and high-velocity supply chain. This enables real-time decision-making and helps us avoid serious and potentially costly risks, like insufficient inventory levels, stockouts, and fill-rate penalties. And, importantly, it helps keep customers happy and loyal to your business over the long term.

Here's how a strong digital strategy can help create a high-velocity, transparent supply chain and prepare your organization for the busy holiday season.

1. Use real-time data to increase precision, agility and visibility into the global supply chain

Because the complexity and volatility of today’s supply chain are unlike anything we’ve seen before, keeping it stable requires new solutions. Previous strategies, which used retrospective patterns to predict the future, simply don’t work anymore. A more robust and elegant system is needed to understand the current landscape and predict disruptions. Capturing data in real time is the first step.

SAS has joined forces with project44, the leading supply chain visibility platform, with a network of 230,000 carriers tracking a billion unique shipments annually across more than 180 countries. The network gathers data at every level, from ocean carriers to rail to ground transportation to regional distribution centers.

It also captures the nature of each disruption – for instance, an ocean carrier experiencing a delay off port, a track failure near a critical rail hub, or a hurricane approaching a key distribution center. Data is captured at the order, line and SKU level and can be updated in real or near-real time.

Without a robust data network, organizations face the challenge of inadequate data and limited visibility, which creates significant risk. To mitigate it, organizations across industries – manufacturing, automotive, retail, life sciences, food and beverage, CPG, oil, chemical and gas – must maintain, monitor and enhance their data. Performing correlation analytics consistently on current and new data sources will allow you to continue to refine the data sources to produce the most accurate results.

2. Make sense of your data with powerful analytics

A vast amount of data is essential, but without a means to analyze it, you won’t be able to draw insights – which is, after all, the goal. Therefore, once a powerhouse like project44 accrues data, it needs to be ingested by an equally powerful analytics platform – this is where SAS and its industry-leading insights come in. With the ability to analyze your data in meaningful ways for your organization, you now have insights to understand, predict, and remain agile. You can accurately predict whether an item is in or out of stock – and if not in stock, exactly where it is along the supply chain.

This is where some of the most fascinating and quickly evolving technologies come into play – AI, machine learning, and digital twins. By merging digital twin capabilities with analytics, you can visualize how your supply chain is functioning and how and where it will be affected if a disruption occurs.

In effect, it allows you to predict a problem before it happens and to react accordingly. It can provide a virtual road test or a potential plan before you implement it so that you can select the best path forward.

In a recent interview, John Dyck, CEO of the Clean Energy Smart Manufacturing Innovation Institute (CESMII), pointed out the importance of comprehensive, data-rich approaches to the supply chain.

“As manufacturers work on trying to be more resilient, particularly in the face of some of these more disruptive situations and scenarios, it’s become very clear that we need more systematic approaches to how we look at data," Dyck said. "We need better analytics and we also need to be more collaborative around our approaches with our suppliers. The idea is to build an infrastructure that allows suppliers and manufacturers to work together and collaborate around a more real-time flow of data so that we can apply more systematic analytics that is central to how we think about digital transformation.”

3. Become an expert at demand planning

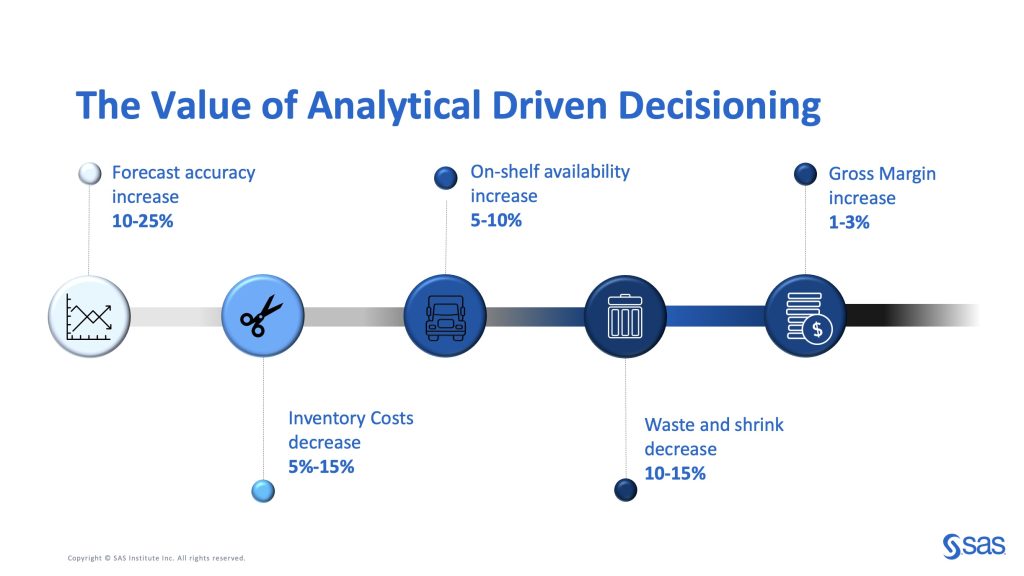

The product of pairing data and analytics is an amazing degree of visibility into the future. Now, you suddenly have the ability not just to see your inventory in motion but also to predict demand. For instance, you can analyze demand data visually to spot patterns and insights related to sales, shipments, pricing, and promotions; evaluate sales history and plan for future events (e.g., new products, locations) using what-if scenario analysis; and measure the effect of sales and marketing strategies on consumer demand using consumption-based forecasting and planning. These capabilities are powerful and precise and, importantly, make your organization resilient to disruption. The measurable benefits include reducing inventory costs, increasing on-shelf availability, and ultimately boosting revenue, among others.

4. Enjoy the efficiencies that help keep customers loyal and employees happy

As the holiday season approaches and the demand for timely delivery rises quickly, digital strategies like the ones described here go a long way toward reducing empty shelves and backrooms and keeping customers happy. Some readers may have experienced how a single misstep can turn customers off, erode loyalty and tarnish a brand's reputation.

But employing data and analytics to help you navigate the unexpected can boost customer acquisition, retention, and wallet share. Even when a product is not on the shelf, with data-driven analytics, you don’t have to tell the consumer, “No.” Rather, you can say that you have it at a particular store, distribution center, or truck and you’ll be able to quickly get it to their doorstep.

WATCH: Building a Resilient and Sustainable Supply Chain: What You Need to Know

A robust data strategy also has measurable benefits for the company, including increased efficiency, reduced costs and happier employees. Digital solutions that can handle the tactical elements free your high-caliber workforce to do what they likely enjoy much more – higher-level thinking and strategizing. As a result, they may be less frustrated and less likely to leave.

In the past five years, the world has seen an explosion of real-time data as well as analytics and insights capabilities. In the next five, they’ll only become more robust and provide a more granular understanding of the supply chain. Employing a digital strategy now will help you lay the groundwork for these quickly advancing solutions and make your company much more resilient.

1 Comment

Richard,

Over the past four years companies have come to realize that the use of near real-time data other than transactional data is necessary to increase precision, agility and visibility into their global supply chains. Traditional analytical models that can only model trend and seasonality can no longer be relied upon to forecast future demand, as consumers shift their demand patterns due to inflation, oil price fluctuations, geopolitical activities, and others. When your trend and seasonality is disrupted, companies need to finding alternative data that reflects the disruption and deploy more sophisticated predictive models and machine learning. Those same models can be used to run scenarios to test the reliance of their supply chains to uncover bottlenecks (weak links) in near real time to create alternative strategies to mitigate the impact.

Investing in cloud native intelligent demand planning solutions that are designed to meet these new challenges will most certainly improve processes and efficiencies, resulting in reduce costs, improved profit margins and revenue.