Today, we celebrate Manufacturing Day 2015. Manufacturing may not be the world's oldest profession, but it is likely the world's oldest industry. The very earliest characteristics that separated us from other animals is the manufacture of tools. Other animals use sticks and rocks and other collected items to help them build shelters and get food. But it is we human's that started to imagine the possibilities if we sharpen flint and forge bronze... in other words, manufacturing precision tools and machines.

Over the centuries, manufacturing has created whole civilizations and economies. Driving innovations and providing all of the things in our lives that we take for granted from the coffee cup you are holding in one hand to the smart phone in your other.

The manufacturing industry is far more than the operational aspects of building and assembling materials into a final product. It starts with an innovative idea which needs to be designed for use and manufacturability. It extends from sourcing the raw materials, to the components and sub-assemblies and to the factory where a final product is made. And do all of that within very small degrees of error to ensure 'zero defects'. But it doesn't end there. The item has to be distributed, sold and supported for its useful life. And more and more, manufacturers need to consider what to do with it when it's useful life is over.

Over a century ago, the world embarked on the industrial evolution, setting the stage for our rampant globalization and mass customization. Now, that is not enough. Manufacturing has always been a very data-rich industry. Monitoring, measuring, reporting and dashboarding of all that material movement, equipment health and production quality. Now, and especially with the advent of the Internet of Things, being data-rich takes on new meaning and could become a burden.

Over a century ago, the world embarked on the industrial evolution, setting the stage for our rampant globalization and mass customization. Now, that is not enough. Manufacturing has always been a very data-rich industry. Monitoring, measuring, reporting and dashboarding of all that material movement, equipment health and production quality. Now, and especially with the advent of the Internet of Things, being data-rich takes on new meaning and could become a burden.

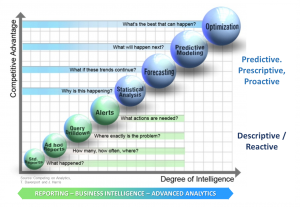

Being data-rich though, means huge opportunity. An opportunity to turn that data into insight, into intelligence and into competitive advantage. In Competing on Analytics, The Science of Winning, authors Tom Davenport and Jeanie Harris describe the degrees of which data analysis can create intelligence and drive competitive advantage. In a white paper from MIT, The Analytics Mandate - The Future of Manufacturing, the authors explore how far the industry has come and the opportunities yet to be exploited.

" One of the things that we always try to look for in a particular project is: Why is an analytics approach superior? And typically it’s because the scale or complexity of the problem escapes just simple human intuition, or the data provides something that is fairly counterintuitive." - Phillip Kim, Senior Director of Big Data and Analytics, Under Armour

The possibilities for analytics are virtually endless. If you can find or create a data source, then analytics will lead you to a better decision. What data do you have that's not being analyzed? What interesting analytics story do you have? Please share!

Happy Manufacturing Day!