Recently I toured a manufacturing plant floor for a company that builds construction materials related to energy. I find a number issues people face in production of which the most common are around asset efficiency, product quality, and safety. This manufacturer like most had similar concerns on all those areas but were currently focused on scrap rates. Manufacturing can control a number of things around product quality and the quality of this product is directly affected by the accurate and precise control of process parameters in the manufacturing process. This process is complex and takes a lot of engineering, automation, and sensors to measure and control process variables like pressure, temperature, and speed, to name a few.

in production of which the most common are around asset efficiency, product quality, and safety. This manufacturer like most had similar concerns on all those areas but were currently focused on scrap rates. Manufacturing can control a number of things around product quality and the quality of this product is directly affected by the accurate and precise control of process parameters in the manufacturing process. This process is complex and takes a lot of engineering, automation, and sensors to measure and control process variables like pressure, temperature, and speed, to name a few.

Control systems have advanced automation capabilities like proportional integral derivative (PID) algorithms that are designed for precise control of these process parameters. PID or sometimes referred to as PID loop control is a feedback system that provides, if properly tuned, an efficient way to correct any error in a process parameter and getting it to the desired set point as quickly as possible. Controlling these process parameters are easy, but what if you can’t directly measure the desired parameter? How would you know you are off the desired setting, much less a way to control for it? Let me illustrate an example:

This company makes a product which is a panel that goes through various manufacturing processes before it is completed. The final process is annealing, or in layman’s terms, heat treating. In this final step the material is cured in a furnace which has a number of heating zones. Then the product goes through a final test and inspection and are packaged and sold.

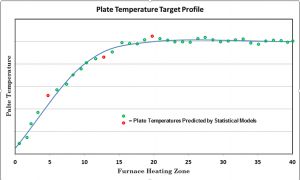

Like I said earlier, this company was focused on scrap. As it turns out some of the products turn out to be of sub-standard quality and can’t be sold as a premium product. They did some research and found that the critical process parameter in this case is the surface temperature of the panels as they passes through the furnace. The surface temperature drifts as they go through each zone in the furnace and surface temperature needs to match a specific profile on the ramp as well as the soak part of this profile. As the product’s surface needs to be exposed to the heat in its entirety, temperature sensors can’t be attached so a direct feedback control loop can’t be implemented to adhere to this profile. If we could put a sensor on it, this parameter could be directly controlled in the automation layer.

Well this caused a number of headaches for the company. Because they could not measure surface temperature directly, a number of products had to be scrapped or downgraded and sold for less money. They would also stop the manufacturing process and go through a calibration process. This process takes dummy panels with built in surface temperature sensors and run them through the furnace. This gave them direct measurement of this critical process parameter and allow them to fine tune the furnace feedback control algorithms (PID) to achieve the desired temperature at each zone and adhere to the profile. There are two impacts to solving the problem in this manner:

Well this caused a number of headaches for the company. Because they could not measure surface temperature directly, a number of products had to be scrapped or downgraded and sold for less money. They would also stop the manufacturing process and go through a calibration process. This process takes dummy panels with built in surface temperature sensors and run them through the furnace. This gave them direct measurement of this critical process parameter and allow them to fine tune the furnace feedback control algorithms (PID) to achieve the desired temperature at each zone and adhere to the profile. There are two impacts to solving the problem in this manner:

- Production is taken offline and capacity is lost to do this process. Asset utilization takes a hit and the company’s return in assets are lower.

- They have no way to control drift in between these calibration runs. Therefore they produce sub-standard product and lose margin by having to sell for less.

Fortunately this company saved the data from these calibration runs. This became the foundation for an analytic process to model panel surface temperature. They took this calibration data and were able to model surface temperature against all the other equipment, process and environmental variables and get a better understanding of the process. Some of these were controllable like furnace temperature, while others were not like ambient temperature and humidity. They took this model and started to evaluate it against live data coming from the furnace and give operators the predicted value of surface temperature at each zone. This enabled them to make corrections (slight adjustments to furnace temperature) and hit the desired surface temperature in each zone.

There were a number of positive results from creating this “virtual sensor”. Using analytics to predict the surface temperature allowed the company to adjust its operations with the following benefits.

- Recovered capacity: The Company had better visibility of the process and a way to manage drift in between calibration runs. Therefore, they could reduce the number and frequency of calibration runs and recover production capacity.

- Maintain margin: This “virtual sensor” allowed for tighter control around the critical process parameter of surface temperature. Maintaining quality allows to sell the panels at a premium and maintain margin levels and brand perception.

- These results hit a number of critical KPIs which include, increased yield, asset utilization, OEE, and production throughput.

There are many things that can affect quality in the manufacturing process and as we saw in this example, process parameters including unmeasurable ones can affect product quality. These parameters need to be controlled tightly as one of the main contributing factors to quality. It is difficult for automation controls to take corrective actions during the manufacturing process for this "unmeasurable” surface temperature. So we turned to advanced analytics, like those in SAS® Product Quality Analytics, which gives us a way to virtualize these process parameters and give us a better understanding of the process. This understanding allows for better real-time decisions yielding high quality products.

I am very interested in your stories. Where have you found the need to derive this sort of virtual sensor measurement? Or maybe this sparked an idea of a challenge you've struggled with, how can this concept help?