The term market driven – or demand driven as some prefer to call it – refers to a situation in which the supply chain responds to the actual requirements of the market. It has been the utopia of supply chain planning for years, and the number of business strategies and change projects (along with more or less scientific papers) with this focus is uncountable.

Being market driven boils down to three things:

- Knowing the true market demand and the demand drivers

- Having a supply chain that can respond to the true demand

- Having processes in place to align demand and supply on day to day and long term basis.

The journey towards market driven

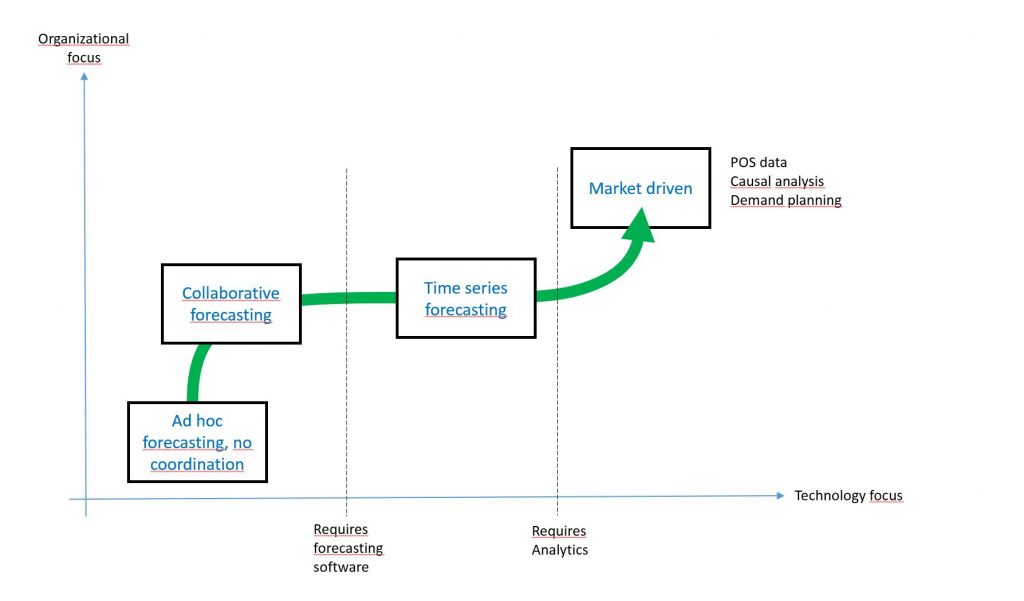

Below is a visualization of how forecasting / S&OP practices have developed in many manufacturing companies. The process develops in two ways: the organisational – dealing with the collaboration, the process and competences of the people involved in the process; the technological – dealing with the software and data that are used in the process.

Ad hoc forecasting - no coordination

This first state is still present – even in large companies today. Various departments do their own forecasting. They are shared with other departments, but are seldom used outside the department where they were made. As a result, business plans lack alignment, and the company plays a blame-game when things go wrong. There are no real incentive to get the forecast right, and forecasts are typically biased towards the needs of the department.

On the other hand – everybody seems to be happy as no one interferes with their “little kingdom” – except for the CEO, who has to deal with differing forecasts and business plans going east and west.

The Journey towards “Market Driven” often starts with the CEO asking for a reconciliation of the various forecasts and some sort of consensus on the numbers.

Explore how artificial intelligence and machine learning applications are reshaping the supply chain of the future. Tune in to this on-demand webinar

Collaborative forecasting

This calls for recurring meetings to align the forecasts. Typically the excel sheets are reconciled and one forecast agreed. During one of the first of these meetings, it is suggested that the forecast is made in collaboration – and thus the company starts implementing a Sales and Operations Planning Process (S&OP).

The purpose of the process is initially to include the knowledge from different departments into the forecast and split the responsibility for the process parts on different departments: Sales and Marketing brings the forecast, R&D brings plans for new products and Operations checks the feasibility of the plans. Gradually over time, the process is improved, and the results satisfy everybody. On monthly meetings, the forecast is discussed and agreed upon, and each department can go back and lay out detailed plans.

Technologically, the process is supported by spreadsheets, which allows for fast development, which is needed – especially in the early stages– as good ideas grow and are implemented.

The biggest change from moving from ad hoc forecasting to collaborative forecasting is cultural. The silo thinking of the previous period is abandoned and replaced by a collaborative process. This takes time, as silos ARE difficult to break down. It is however, one of the major steps towards becoming market driven.

The biggest change from moving from ad hoc #forecasting to collaborative forecasting is cultural. #ConnectedSupplyChain Click To TweetThis process actually works very well for many companies. The benefits of having one forecast and the alignment that goes on in the meetings goes a long way to satisfy the needs of the company. Further, as the detail level is quite rough (monthly time-buckets – aggregated product levels), stakeholders have some freedom when specifying the more detailed plans. The process and spreadsheet is continually refined, organizational relationships strengthened and the results in terms of business plan alignment improved. Yet, some companies seek to go beyond this level. The reasons are amongst others:

- Lack of details in the forecast – which leaves the door open to too many interpretations.

- Forecast accuracy level not high enough / biased forecasts / hockey stick effect.

- The spreadsheets become too difficult to manage.

Somebody in the organization suggest using forecasting software as it – in theory – addresses the shortcomings of the collaborative forecasting process.

Time series forecasting

I realize that time-series forecasting may also be a part of the first two levels… it has been the case in some of the companies I have worked with over the years. However – in these phases, they are not regarded the backbone of the process – but something used in the planning department to break down forecasts to the needed granularity.

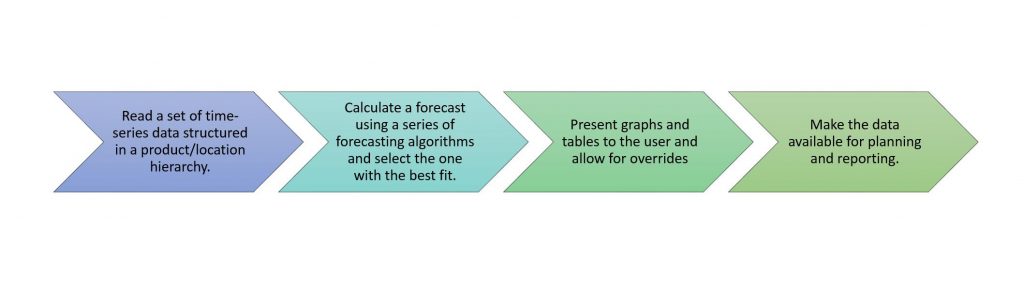

Forecasting software – while they differ in their range of functionality, price and ability to integrate to other IT systems, the base functionality is always similar – and consists of the following steps:

By putting the forecasting software as the core of the process, companies are able to tap into mathematical models, which will help to calculate an accurate forecast, identifying trends, seasonality – and shifts in those. As the forecasting software has no opinion, the forecasts are free from bias, and thus serve as an excellent baseline for the forecast – which is then modified with domain knowledge – i.e. knowledge about the market and products.

As the software can handle large amounts of data, it can forecast at a much more detailed level (SKU / Distribution node), and forecasts can be reviewed at any level due to the hierarchical data structure.

In its essence this means, that companies address the major issues of the collaborative forecasting approach.

Moving to times series forecasting into the core of the S&OP process requires yet another change in the perception the stakeholders' role, as decision making is moved to a software, that no one really understand in detail, but seems to be better at understanding demand than any individual in the company. The new way of forecasting calls for different competences in the organization, and the dedicated demand planner is introduced to handle the forecasting process. The demand planner works with data in the forecasting software and collects information from other stakeholders to incoporate the knowledge in the forecast.

Forecast overrides

A forecasting algorithm rely on the premise that the world is stable – i.e. that the demand drivers do not change over time. In order to incorporate the knowledge the company has on things that will affect demand, the third step of the process – making overrides – becomes important. Frankly speaking – the forecasting algorithms are saved by the ability to make overrides – otherwise, the trust in the process would be gone very soon.

The reason for wanting to do more originates in the manual overrides functionality of the forecasting software. In some companies the override functionality becomes the cornerstone in the forecasting process which pulls the forecasting project back towards the collaborative forecasting process.

The reason for wanting to be market driven

The underlying reason is however often that the marketplace is changing. It is becoming more complex.

Shortening product life cycles, increasing demand volatility, technology disruptions and so many other things are working against the premise of stability that the forecasting software relies on. In the organization, speculation about things affecting the demand increases – but proofs are hard to come by. There is an increasing frustration about not being able to “hit the target” in terms of forecast accuracy – which in terms reflects in increased cost (inventory, supply chain and transportation) – while at the same time delivery performance is hard to keep at the requested target.

In the later years – being demand driven – has been synonymous with solving these issues. In the next article I will explore the road from time-series based forecasting to demand driven.

Read more about operational and planning efficiency and increased profitability.