In recent years, we have seen huge changes in the areas of logistics and supply chain management. And it is no exaggeration to say that those are only the tip of the iceberg. These changes are the result of a number of factors coming together. Arguably the biggest trigger for these changes is the current experience with nationwide lockdowns across many countries. I asked Tim Clark, our resident expert on supply chains, to walk us through what is happening.

What are you seeing as the big enabler?

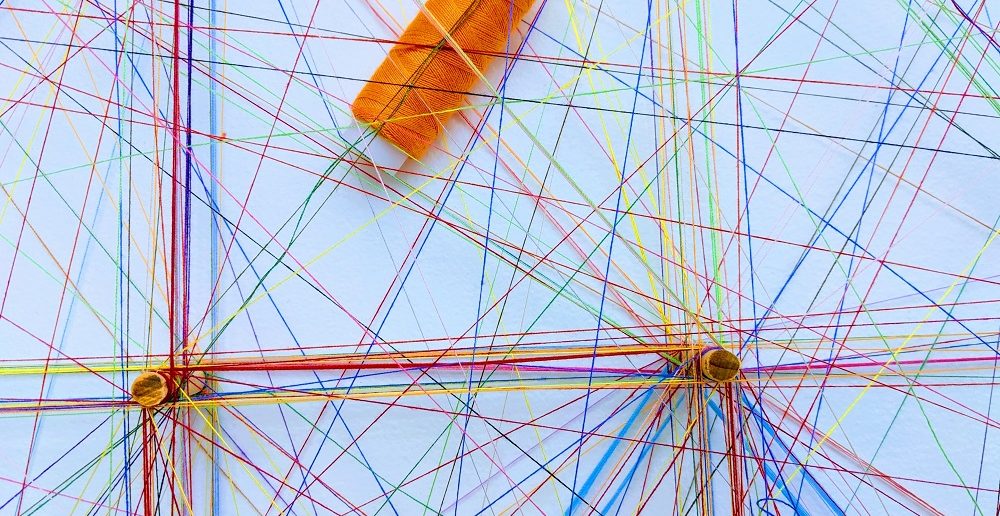

The first factor is the explosion of data resulting from the Internet of Things. The vast network of connected sensors and involved devices is altering the way that we think about supply chains and how they are managed. We can now see much more about what is going on, and that inevitably means that new opportunities are opening up, as well as new challenges. The artificial intelligence of things (AIoT) is also adding new opportunities and challenges. More data is available from both inside and outside the enterprise, understanding has increased around the value of analytics in the supply chain, and more analytical processes are available. Therefore, adoption is increasing, but slowly.

Sounds terrific. What’s holding up progress?

These changes have paradoxically increased both complexity and visibility. The number of players involved in the supply chain has increased, as have the options available, resulting in many supply chains becoming more akin to networks than chains. However, at the same time, the new data available means that more of the supply chain can be seen by everyone involved. These changes require new ways of thinking and working to manage the more complex supply chain-based ecosystem. However, they also provide an opportunity to rethink supply chain management though these ecosystems and how value-add is truly driven. In some ways, you have to think about opening up and sharing more data to your network to get more value back in insight, efficiencies and benefits.

How has the landscape of participants changed?

Logistics is viewed as operating across five different levels. At the lowest level, first-party logistics, companies manage all their own logistics. They own the cargo, and they own the means of transport, and use it to move their goods around. In second-party logistics, the transportation element is outsourced to carriers. At the third-party level, we start to see specialist logistics providers emerging. At this level, companies outsource the management of their logistics to a third-party organisation, which controls all transport and decisions about when and how to move goods.

The term "fourth-party logistics" was coined by Anderson Consulting (now Accenture) in 1996 to describe the emergence of specialist supply chain management services. They were originally defined as supply chain integrators, pulling together and managing their own resources, capabilities and technologies, as well as those of other service providers to manage the supply chain in a comprehensive way. These service providers therefore operate across the whole supply chain, managing every aspect from procurement through storage to distribution. A fourth-party logistics provider may or may not own all the elements of the supply chain. The important aspect is that they manage and optimise the supply chain across all these elements.

Now, however, a further level is emerging: fifth-party logistics. Fifth-party logistics providers have developed to manage the increasingly complex supply chain ecosystem or network. Their focus is to take insight to the next level by looking at "sensing" change in the value chain and providing insights to react quickly. The sensing can come from anywhere but has an impact on the efficiency and effectiveness of the supply chain. Fifth-party logistics providers are therefore often the leading fourth-party providers, looking to add even more value for their customers and make sense of the complexity.

As levels of complexity increase, allocation of resource and focus changes; where automation can be used, leveraging AI and machine learning use it. This frees up time to focus on more complex processes that really need human attention.

Have supply chains been good at exploiting technology?

Managing the increasingly complex supply chain network is only possible with the use of technology. Fifth-party logistics providers have a strong focus on technology solutions, and especially the use of the IoT and advanced analytics, including AI. These technologies assist in automation and increase visibility across the whole network. They therefore have multiple effects.

As levels of complexity increase, allocation of resource and focus changes; where automation can be used, leveraging AI and machine learning use it. This frees up time to focus on more complex process that really need human attention. Capabilities and solutions like shared portals and collaboration workbenches improve teamwork across the network. They make it possible for different parts of the supply chain to work together more easily, and also to understand each organisation’s role in the network.

The use of analytics, especially advanced analytics on sensor data, enables the right decisions to be taken at the right time. This often means in real time, but also allows just-in-time decision making and rapid action. In particular, these solutions focus on getting better value out of the data. They allow the network manager to reduce uncertainty across the whole supply chain, from upstream through the company itself, and further downstream.

What’s the outlook?

The overall effect of both increased visibility and better collaboration is a massive improvement in efficiency across the whole supply chain network. This, in turn, increases profitability for everyone involved and makes it likely that more organisations will be looking to these solutions in future.

All companies are now facing completely new challenges. Analytics is what we know and we are using our most advanced technology in innovative ways to help our customers across every industry combat the coronavirus outbreak. Read more on our COVID-19 Data Analytics Resource Hub.