By now, we're all aware of the seismic shift occurring across industries as a result of the Internet of Things. But do we all see the changes in the same light?

From where I sit, there's still a wide gap in viewpoints and perspectives. In its simplest form, we often hear the Internet of Things described as a network of connected “devices” that enables connectivity, interaction and exchange of data.

But being connected and exchanging masses of data is only the start to the IoT story!

What's the future of the IoT story?

In my view, the Internet of Things should be focused on the use of real-world data generated from connected devices to support processes or services that create valuable outcomes for industry. And driving those valuable outcomes is where the artificial intelligence comes in.

The convergence of Artificial Intelligence (AI) with the Internet of Things (IoT) creates the Artificial Intelligence of Things or AIoT. Artificial Intelligence is the science of training systems to emulate human tasks through learning and automation. The key word is training, which has been a historical challenge with AI systems, due to the volume of data and computational power required. Enter IoT!

AIoT in transportation powers safety and service

For the transportation industry, the connected vehicle is becoming the single biggest disruptive force in over 100 years. Vehicles are no longer just a means to get people or goods from point A to point B. They're becoming a digital platform for innovation across an industry that offers new services, applications and value: $5.4 trillion in potential transportation services revenue by 2030, according to McKinsey & Company.

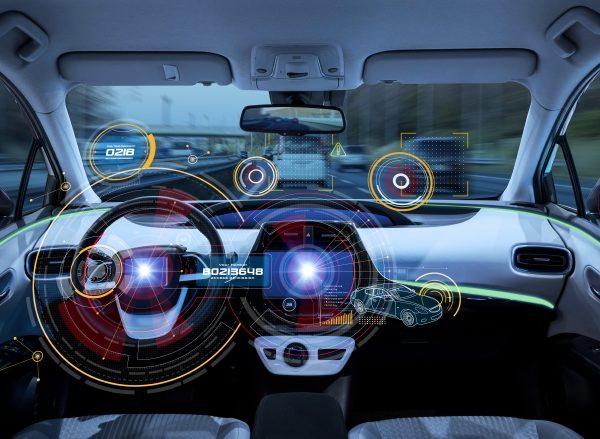

Autonomous vehicles have captured lots of buzz in the market … and rightfully so. The level of sensing, connectivity and analytic infrastructure required to enable the automated safety features inside vehicles is truly astounding. However, it doesn’t stop there. Beyond safety and security, think about the customer experience within the vehicle --- from in-vehicle connectivity, to infotainment, to personalized engagement/services, to automatic maintenance notifications and scheduling.

That level of interaction is changing the game for service providers as well. Access to vehicle usage data and driver behavior is transforming the insurance industry through tailored coverage options, improved claims handling and more. Dealer networks are now able to lower costs and optimize operations through improved forecasting of customer service demands, improved inventory management and streamlined troubleshooting.

Transformation isn’t limited to consumer vehicles. The commercial transportation industry remains critical to the world’s supply chain; and with increased automation coming to trucks (Volvo/Mack) and other heavy freight movement solutions (GE Transportation), the industry is focused on driving changes leveraging the AIoT. With embedded AI on the edge of the network, machines can learn from experience, adjust to new inputs and accomplish specific tasks without manual intervention. Enabling smarter and safer decisions, protection against intermittent cloud connectivity and control over rising communication and data transmission costs.

SAS and Jason Mann invite you to attend the 2019 IoT Solutions World Congress in Barcelona. See our keynote presentations, featured sessions in IoT and Health Care Tracks and meet us and our IoT partners at booth C311.

Benefits of AIoT in transportation

Some practical applications for AIoT in the commercial transportation industry include:

- Supply chain planning: Optimize supply chain operations with real-time visibility into fleet/cargo location and traffic data, enabling improved delivery estimates and mitigation of service disruptions.

- Equipment reliability: Leveraging real-time operating data to drive improved maintenance planning and execution (predictive maintenance) to increase up time and utilization of assets.

- Safety: Combine equipment operating data, location data, environmental factors and characteristics of freight to assess real-time safety concerns, such as speed violations, derailment risk, cargo stability, hazardous material spillage and more.

- Fuel management: Reduce fuel consumption (largest operating expense) through adaptive operations based on environmental and network status. Optimize fuel planning across delivery routes based on real-time pricing and refueling times.

- Driver compliance: Monitoring driver behavior to ensure compliance to regulatory or business operating procedures to minimize excess wear on critical business assets.

- Track/road inspection: Lower maintenance budgets through improved track or roadway inspection procedures that use deep learning vision systems, correlated to location and operating data, to provide automatic detection of degraded infrastructure.

The common theme for all the use-cases and applications highlighted is that they wouldn’t be possible without analytics. With AI-powered capabilities, IoT data can be transformed, analyzed, visualized and embedded across the entire ecosystem – edge devices, gateways and data centers, in the fog or in the cloud – in order to achieve business value.

I am excited to watch the evolution of the AIoT moving forward, and I honestly have no idea where the journey will lead us. I think we are just scratching the surface of what is possible and can say with certainty, that the path we take will always run through analytics!

Learn more about how SAS is pioneering AIoT.