I was privileged to attend the National Association of Manufacturers (NAM) Board of Directors meeting in Washington D.C. recently. Attended by some 300 senior executives of American Manufacturing companies, it was like a who’s-who in brand names anyone would recognize. NAM is a very big influencer of public policy on the national, state and local levels as manufacturing is a key industry to the US economy. I have stated this before, you cannot achieve and sustain economic leadership without a robust manufacturing sector. And yes, the conventional wisdom of the day is all about the decline of US manufacturing. Another piece of populist lore we will increasingly hear this next 12 months is the claim that companies are “shipping jobs overseas” with the implication that we need more laws and regulations from the candidates that promote this idea.

But what I heard last week were facts about US manufacturing that tell a much different story:

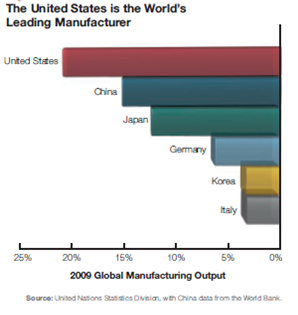

1. The US is still the leading manufacturing nation on earth, while China and India are growing much faster in their manufacturing. This is good, not bad. They need to grow. They each have huge populations and emerging middle-classes that want a better standard of living. The economic pie of world wealth is not fixed, it is dynamic and getting bigger and we should be glad they are growing their middle class. But this hardly means the US is becoming irrelevant in manufacturing. The US produced 19 percent of the worldwide value-added manufacturing output in 2008 and about 22 percent of that was exported. The US is the 3rd largest exporter and the number one manufacturing economy in the world:

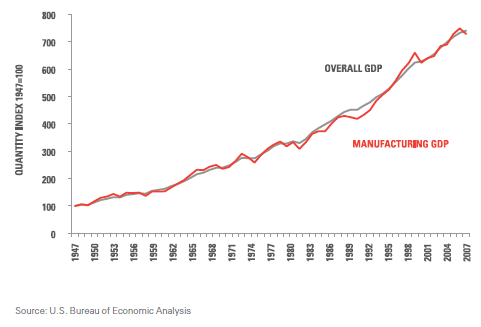

2. The percent of GDP that manufacturing occupies has remained about the same for the past 30 years. Manufacturing is often compared to agriculture in terms of a slow decline in its share of employment and national output. However, after adjusting for price changes, the quantity of manufacturing value added (GDP) has generally kept pace with the overall economy during the past 61 years, taking into account both recessions and expansions. Manufacturing GDP does fall faster during recessions (like the current recession), but it also grows faster in expansions (source: NAM Report on Facts about Modern Manufacturing).

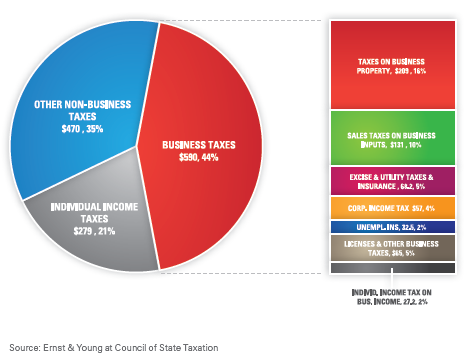

3. Businesses provide the bulk of taxes that fuel state and local governments. Without a healthy manufacturing base, which make up 20 percent of business taxes, we would be in a much more precarious position than we are now. See the chart below for Total State and Local Taxes FY 2008, in bils:

4. Another myth exploded is the idea that U.S. manufacturing investment abroad destroys US jobs. Consider these facts:

- US multinational corporations (MNCs) employed 22.4 million Americans domestically in 2008 and nearly 12 million were employed directly in manufacturing. Of that 12 million, 7 million worked for MNCs

- MNC affiliates employed 5.4 million manufacturing workers overseas with nearly half of them employed in high wage countries in Europe or in Canada. Only 10% were in China, less than Germany and France combined.

- From 2000-2008, manufacturing jobs overseas in MNC affiliates increased by only 314,000; this is barely 6 percent growth and one-third of this was in Europe.

- MNCs with operations in many countries had much higher labor productivity than those with operations in only a few countries ($154K versus $100K average value added)

- Companies invest abroad to serve local markets. U.S. affiliates sold $2.7 Trillion in manufactured goods in foreign markets in 2008 and 90% of sales were to local markets not exported back to the U.S.

- Companies invest abroad to seek a skilled workforce, not cheap labor. U.S. manufacturing foreign direct investment (FDI) stood at $541 billion in 2009; 72% by value was in developed countries and U.S. manufacturing investment in China was only 4% of total FDI; 75% of value added of all affiliates was in high-wage countries.

5. MNCs remain committed to producing in the United States and are investing in the future.

- Jeff Immelt, Chairman and CEO of GE spoke at the meeting and made a clear, direct statement to this issue and listed a number of areas that GE has invested heavily including expanded locomotive and aircraft engine operations because they have received so many orders overseas.

- Overall, U.S. manufacturing shipments totaled $5.5 trillion in 2008, up 30 percent from 2000 and MNC sales accounted for about 75 percent of the total for manufacturing.

- MNC research and development expenditures in the US in 2008 were $236 billion, and 77 percent or $183 billion was in manufacturing.

- MNCs overseas investments are NOT the cause of the trade deficit. Consider that MNCs exported $507 billion in manufactured goods from the US in 2008. Their affiliates took nearly half of those exports. Manufactured goods trade accounted for only $72 billion of the $698 billion trade deficit in 2008 and if you exclude petroleum and coal products, MNCs actually produced a trade surplus of $106 billion in 2008.

I know that was a firehose of numbers and facts but we simply must make the critical decisions about our future that we need to make based on facts. From my vantage point, that is what leading edge companies are doing and we must hold our politicians to that standard as well. I will have more to say about what was said at this conference concerning what is hindering the growth of manufacturing in the US, which by the way, is the engine that has largely pulled not only the US economy out of the ditch but the world economy as well. And if we don’t pay attention to what manufacturers are saying about what hinders them from creating new jobs and innovating new products we do so at our own peril. No, manufacturing is not even in the hospital, let alone dead. But if our public officials play fast and loose with the truth and use MNCs and in particular, manufacturing MNCs as a punching bag, we can certainly make her very sick.

Next week I will be reporting on the SAS Premier Leadership Series from Orlando where General Colin Powell will be one of the keynote speakers. We will have the opportunity to rub shoulders with our customers and learn more about what keeps them up at night (sorry for the cliché).

All the best, Mike

4 Comments

Hi Michael - I work for a structural steel supplier and manufacturer here in Texas. This is a great article that presents what is right with American manufacturing in a clear light. I think that the jobs section is extremely important - while the manufacturing still employs millions of people, currently there are 600,000 jobs that are "un-fillable" due to a shortage of skilled workers here in the US. We have to understand the needs of the manufacturing industry and meet those needs in order to fully recover economically - it can't be done without US manufacturing.

Anyways, thanks for sharing! - Aly

Thanks Aly! I am getting tired of so much dis-information out there. It cannot have a postive effect on young people who are considering a career in manufacturing. In Japan, manufacturing engineering is considered a high status occupation; they revere manufacturing and realize as a country how important it is to them. Every American has a vested interest in encouraging our manufacturers.

Hi Michael, Thanks for a nice article with numbers showing positive perspective. I feel that the mass manufacturing will keep on moving out of America, but high end manufacturing driven by innovation would be around for lot of years.

Thanks for the response Akash. I agree that some mass manufacturing will continue to leave the USA but I would offer Germany as a prime example of a nation that prioritizes manufacturing can maintian a strong base of mass production and we can see the consistent results as the highest per captia rate of value added exported manufactured goods even though it is a costly place to do business. Of course, some segments of manufacturing need to be local for a variety of reasons including dollar-denominated exchange risks. BTW the Japanese and other auto transplants are a great example of how building product where you sell it works out well. 10 companies operate 16 plants in NA today and account for 48% of all new vehicle sales (Autodata report).