Bengt Persson, the Senior Vice President of Quality and Tech Support, presented a session about driving quality across the globe during the 2011 Premier Business Leadership Series in Singapore. Persson told the story of how Volvo Trucks uses analytics and data flow to standardize and optimize warranty claims across Volvo’s 180 global markets. This significantly reduced warranty claims, improved products and services and increased customer satisfaction.

Volvo is the biggest company on the Swedish stock exchange. To hold that edge, the company must constantly evaluate and improve products and procedures. Volvo Trucks produces five truck brands and a line of buses, construction equipment, the Volvo Penta (a motorcraft engine) and Volvo Aero (an aircraft line). Additionally, Volvo Trucks offers aftermarket transport solutions including financing, insurance and service packages. According to Persson, these aftermarket solutions have become as important - if not more so - than the core products.

To ensure customer satisfaction, Volvo keeps its service network close to the customer. Volvo works closely with the dealers and service centers to ensure standardization. According to Persson, Volvo is proud of its service network, yet the company saw room for improving customer service using analytics.

Coming up to speed

With more than 2300 dealers and workshops across 180 global markets, standardizing the warranty claims process would not be an easy task. The first step, according to Persson, was gathering current warranty claims data – this took about three years. Previously, each market had its own system for processing warranty claims and gathering data. Today, all 180 markets collect the same type of information.

The warranty claims information and data about the chassis, parts, suppliers, product variants and internal quality information are fed into the SAS database. This data is now available for analysis and reporting for three skill levels of users at Volvo Trucks: analysts, researchers and corporate users.

Standardizing warranty claims reduces losses by improving service time, reducing redundancies in parts distribution and finding potential for fraud. “The most important thing about improving the data flow is being able to get information to improve the quality of our trucks,” said Persson.

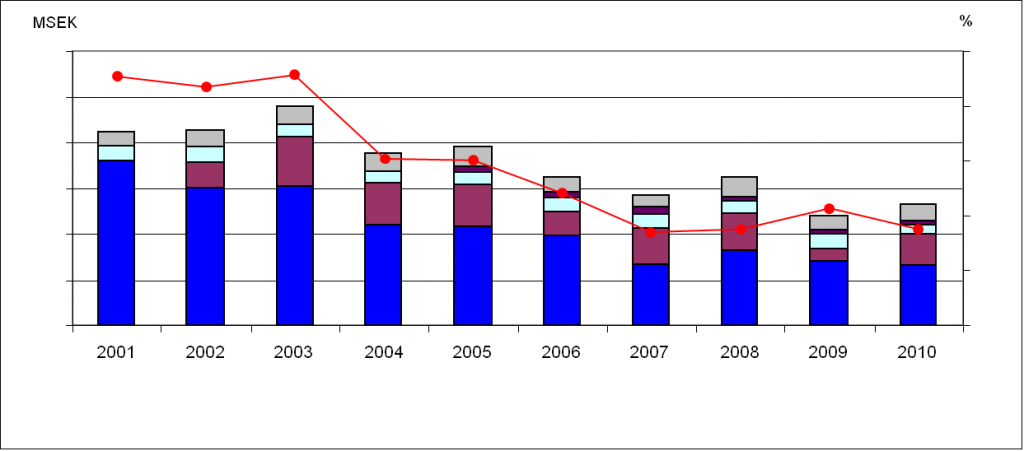

According to Persson, this has significantly reduced Volvo Truck’s warranty costs. Although he could not discuss the ROI in a dollar amount, Persson shared the graph below that charts the warranty cost in relation to the percentage of sales from 2001 to 2010. “This goes hand-in-hand with customer satisfaction,” he said.

The long haul

In the past automobile manufacturers, including Volvo Trucks, sold extended warranties as a customer service. These warranties typically begin after the manufacturer’s warranty expires. According to Persson, Volvo Trucks now tries to avoid offering extended warranties. “We’re now selling more and more service contracts,” he said.

“What we get with service contracts are a relationship with the customer. We put that same data in the data flow,” said Persson. “We can now connect the data from the services into the database and diagnose quality issues.”

For instance, Persson said that Volvo found that there were inordinately high warranty costs for Australia. When the service dealers were contacted, they reported that the conditions in the country required the drivers to run heavy loads at high speeds in high temperatures. After analyzing the data from the trucks, Volvo Trucks was able to change the rear axle ratio to be more suitable for Australia’s trucking conditions. This reduced warranty costs for Volvo and increased customer satisfaction.

“Our ambition is to use these statistics more and more for durability – be more preventive versus corrective – and optimize the business using service contracts,” said Persson. “We’re also looking forward to putting in on-board diagnostics.”

1 Comment

Can`t disagree with you. Volvo trucks is alll about quality and innovation. We are proud to use them in our fleet!